PRODUCT

Flexible Printed Circuits (FPC)

White/Transparent GreenWhite

| → Product Number | SS-350W | SS-400W | KS-850G | KS-800G | MS-400B | MS-900G |

| → Color | White | White | Transparent green | Transparent green | Black matte matte ink | Transparent green |

| → Use | Light bar for folding text, folding line | Replaces white PI | Protect ink | Protect ink | Matting application of reinforcing plate | Protect ink |

| → Substrate | Cu,PI | Cu,PI | Cu,PI | Cu,PI | FR4 | Cu,PI |

| → Ink spill(< 0.2 um) | V | V | V | V | - | V |

| → Flatness( < 2 um ) | V | V | V | V | - | V |

| → Extinction Rate | - | - | - | - | < 14GU | - |

| → Reflectivity(>70%) | V | V | - | - | - | - |

| → Beat | V | V | V | V | V | V |

| → Electricity | V | V | V | V | - | V |

| → MEK resistance test(cotton swab back and forth 5 times) | V | V | V | V | V | V |

| → Electroplated Gold | - | V | V | V | - | V |

| → Chemical gold plating | - | V | V | V | - | V |

| → Liquid drug release test | V | V | V | V | - | V |

| → Tin pot test | V | V | V | V | V | V |

| → Resistance to bending after thermal exposure | V | V | V | V | X | V |

| → RoHS | V | V | V | V | V | V |

PET Optical Film

Highly translucent PET optical film for the optoelectronic industry

| → Physical Properties | Project | Characteristic |

| → Thickness | Thickness uniformity, surface roughness | Thickness uniformity can be controlled to ± 2%, low surface roughness. |

| → Mechanical Properties | Tensile Strength | Resistance strength reaches more than 18 kg/m² |

| → Thermal Stability | Heat shrinkage | Excellent dimensional stability, heating shrinkage can be controlled below 1%. |

| → Release | Release force, release surface stability, release surface scratch resistance | Provide products for light, medium and heavy release force requirements. Weather resistant, low transfer. Resistant to abrasion. |

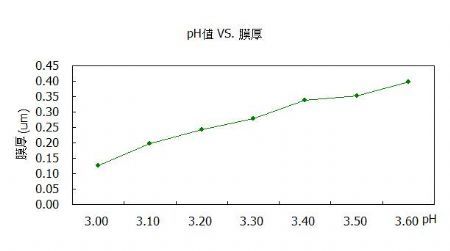

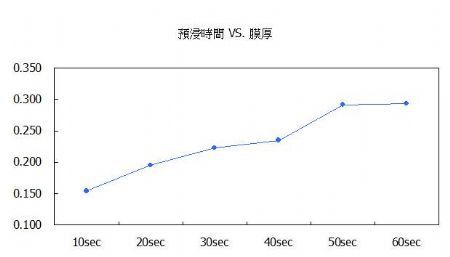

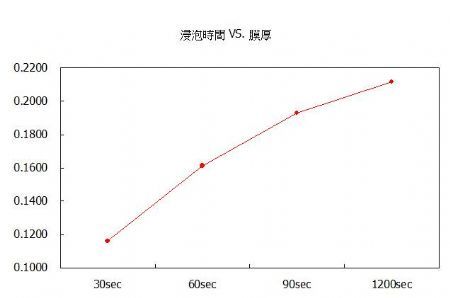

Organic Solderability Preservatives (OSP)

Application:

Lead-free soldering pads for printed circuit boards (PCB) and IC carrier boards

Features:

- Low cost surface treatment technology

- Uniform protective film provides the flattest pad surface

- Lower surface ionic contamination

- Only a film is formed on the copper surface to prevent discoloration and contamination on the gold surface.

- Excellent heat resistance, still has excellent solderability after multiple reflow treatments

- Excellent moisture resistance, with the ability to protect copper for one year

- Compatible with lead-free SMT process

- Compatible with No-Clean SMT process

- Water-soluble solution of non-volatile solvent, highly safe

- Low temperature operation increases the structural stability of the circuit board

- Mild chemical properties, non-attack solder mask green paint

Process Flow:

Chemistry:

Reference:

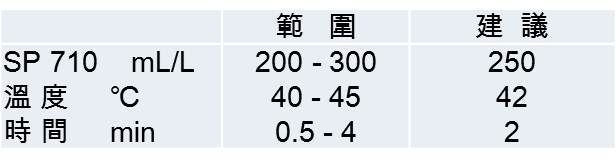

Sealing (Reagent)

Characteristic:

SP 710 sealing agent is a water-soluble formula that does not contain organic solvents. It is different from traditional products containing trichloroethane or oil. It is an environmentally friendly agent. Before using SP 710 sealing agent, the precious metal surface must be completely degreased and Wash with water and then soak in an aqueous solution containing SP 710 to form a protective film that can effectively prevent rust on the surface of precious metals caused by oxidation or sulfurization; the working bath liquid of SP 710 sealing agent provides antioxidant and anti-sulfurization for precious metals. The film also has a special lubricant effect and does not affect soldering properties, so it can be widely used in electronic products.

Antioxidant (Anti-Tarnish)

Tin, silver and gold protective agent AGP 1103

Feature:

- Water-soluble organic solvent-free tin, silver and gold surface antioxidant.

- It is suitable as an antioxidant for pure tin-silver-gold and tin-silver-gold coatings to prevent the surface of processed items from becoming black due to sulfides in the air during processing.

- It is easy to track the concentration of the medicinal solution, and the loss of concentration can be replenished by addition.

- It is widely used in the manufacturing process of electronic products.

Opearting Conditions:

- Place the cleaned and activated substrate into an aqueous solution containing AgP1103 at 42°C and soak it for 1 minute.

- Rinse with hot water for 1 minute.

- Wash with pure water for 1 to 3 minutes.

- drying.

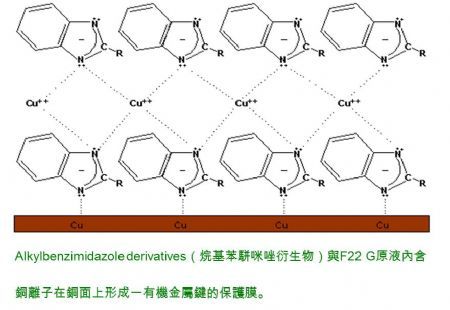

Copper Protectant AT-6400:

AT-6400 is a water-soluble formula that protects copper surfaces from oxidation, contamination and corrosion. If other appearance plating is required after AT-6400 treatment, alkaline degreasing or mild acid can be used to easily peel off the protective film. Because copper is most likely to corrode and turn green on the copper surface in humid air, especially in industrial atmospheres containing hydrogen sulfide, which will deteriorate the gloss and contact resistance of copper. Antioxidant AT-6400 can provide an anti-corrosion organic metal film on the copper surface, so that the copper surface will not be rapidly oxidized before the next production process and affect the quality. This protective film not only provides protection on the copper surface, but also improves adhesion during subsequent processing processes.

Feature:

- Can be used on inner layer boards, after PTH, and before soldering.

- This organometallic film is easily removed in alkaline solution.

- This compound combines with the copper surface to form an organometallic film.

- The concentration of the bath solution can be determined analytically.

- The board surface can be tested with silver nitrate.

- Can preserve its solderability.

- Simple operation and high reusability.

- No need to spend expensive equipment.

- Low temperature, low concentration operation.

Operating Procedures:

- Copper surface cleaning: alkali or acid degreasing.

- Antioxidant: AT-6400, 0.5% ~ 2% (temperature 20~40℃ 10~30sec).

- Pure water washing: PH >5.

- Hot air drying: 70 ~ 90 ℃.

Micro (-Etchant)

| → Product Number | fc-6520 | fc-6542 | fc-6548 |

| → Main Ingredient | H2SO4 + H2O2 | H2SO4 + H2O2 | H2SO4 + H2O2 |

| → Operating temperature | RT | RT | RT |

| → Etching rate(A/sec) | Customized deployment | Customized deployment | Customized deployment |

| → Copper ion controlled concentration(g/L) | 5~30 | 5~30 | 5~30 |

| → Feature of Product | Stable etching value, pre-OSP etching micro-etching process | High roughness, suitable for pre-treatment of ink | Stable etching value, pre-OSP etching micro-etching process |

Acid (Clean)

Illustrate:

The acidic cleaner Cleaner EC-201 is used to remove oxides on copper and contaminants from the previous process. It is especially used in combination with OSP Organic Solderability Preservatives and can be used to clean optional boards.

Feature of Product:

- Low foaming type

- Does not contain hydrochloric acid

- Low surface tension

- Good hydrophilic ability

| → Operating parameters | Recommended range |

| → Dosage(ml/L) | 300 ~ 400 |

| → pH value | 0.5~1 |

| → Temperature(℃) | 35 ~ 45 |

| → Time(sec) | 30~60 |